drilling a borehole

SITING YOUR BOREHOLE

There are two common techniques of siting in Zimbabwe, the Traditional Method and the Geological survey Method.

The traditional method, or water dowsing /divining makes use of the Y branch, a water filled bottle, L rods, pendulums etc. This method is used extensively in Zimbabwe and is surprisingly effective. Good water dowers with experience are able to predict breaks, depths and expected yields to a great degree of accuracy.

One must use caution in high mineral bearing areas as minerals in the earths crust can mimic the feel of breaks and errors can occur.

Geological surveys make use of resistance mapping to locate flaws and soft zones in the earths crust in which water may be resident. This method of surveying, being scientific is usually more expensive than the traditional method as more manpower is required and the time needed can be extensive.

Lastly, ensure your Dowser is readily available in case a decision to drill deeper is required. Professional dowsers make themselves available ‘with warning’ and have no problem with this.

WHEN SITING YOUR BOREHOLE

CONSIDER THE FOLLOWING

1. Polution sources

2. Location

3. Access

4. References of the siter

5. Siters statistics of success

6. Guarantees and money back

7. The yield and depth of other boreholes in the

area

8. Securing the hole in the future

9. Distances from both power and water points

Insist on a site report including a location sketch, GPS coordinates, breaks, expected water yield and depth. This information is needed for your ZINWA drilling

permit.

NEXT STEP IS

Applying for your Drilling Permit

Vortex offers to facilitate these applications for customers.

Harare falls under two Zinwa Catchment Councils relating to the two catchment systems about the city, namely the Upper Manyame and the Nyagui.

Applications can be made directly to them. The Nyagui catchment falls in the North Eastern sector of the city and is bordered by the Acturus Road, Raintree, Kew Drive, Ridgeway North section and the Borrowdale Road. Property outside of this sector this falls under Upper Manyame.

THEN ON TO..

CAPACITY TESTING

An often overlooked step, Capacity testing is used to determine the maximum sustainable drawdown on the borehole and the dynamic stabilised water level too.

This information is gathered over a period of hours and is useful information to both the user and the installer. It is required to accurately determine the pump and motor combination ensuring longevity of both the borehole and pumping unit.

During the process of capacity testing, water born particles, cuttings and silt are pumped out of the hole along with the water. This can prolong the life of your

own wet end.

LASTLY

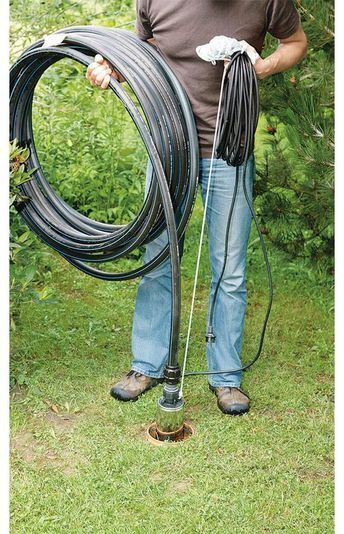

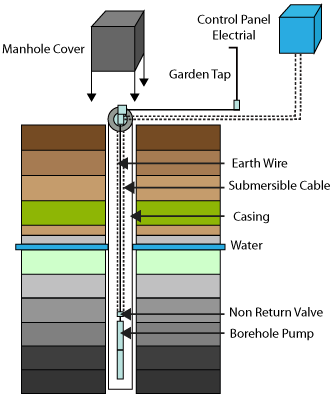

PUMP INSTALLATION

There are so many variables and ideas of what’s acceptable and what’s not in Pump Installations that it’s impossible to cover everything.

Only entertain reputable installers who offer good backup services, use good quality pumps and come with a good reputation as there are so many hit and run Installers out there.

1. Discuss the installation at length with your chosen installer.

2. Show the installer the drilling report and capacity test.

3. Discuss and settle on the type of pump to be installed. Ask where it’s made.

4. Insist on proper submersible cabling down the hole.

5. Insist on a proper manhole and security cover. These help stop contamination and theft.

6. Make sure there are bleed valves on the pressure tank. These are very important.

7. Keep a record of the pump and motor reference numbers.

8. Ensure the pump is lowered to the correct depth.

9. Electrics must be handled by electricians only, especially in your house.

Most importantly, be there and find out where everything is laid and how the system works.

Warranties and Guarantees

Vortex warrantees all holes and all new installations from date of completion. This warrantee stands for one year and is against all workmanship by Vortex.ells users how easily they can get in touch with you

OTHER INFORMATION

Flushing

There are a number of reasons for flushing a borehole, however, the main reason is to purge the hole of siltation which occurs over time. Sometimes a borehole

is sunk where there are high levels of fine water born particles that require extensive pumping and flushing to eliminate. When flushing, compressed air is

pumped down the borehole to blow out the sands and silt that has accumulated at the bottom. Normally it is most effective.

Re casing

Re casing is most often not possible in the literal sense, but is a term used in the borehole industry to signify the placing of a second lining within an existing

primary lining. A borehole requires relining when the integrity of the original lining is compromised. Over time, steel casing can corrode to a point where detritus

and alluvium together with gravel packing are no longer retained and make their way into the borehole.

Sometimes a borehole which hasn’t been cased throughout can spring a leak through fractured or linings that haven’t seated properly.